Description

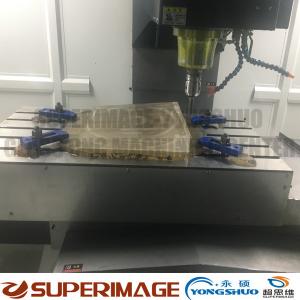

From prototype to high-volume production Raytek Optics is dedicated to manufacturing custom plano optics to meet your precise specifications. Since 2017, Raytek Optics has built a worldwide reputation in custom optics manufacturing pairing traditional craftsmanship with leading-edge technology. Our 50,000 sq. ft. facility houses the larger collection of cnc cutting machines,cnc milling machine centers, double-sided polishing machines,PIB polishing machine, MRF polishing machines, etc in Shanghai,China.

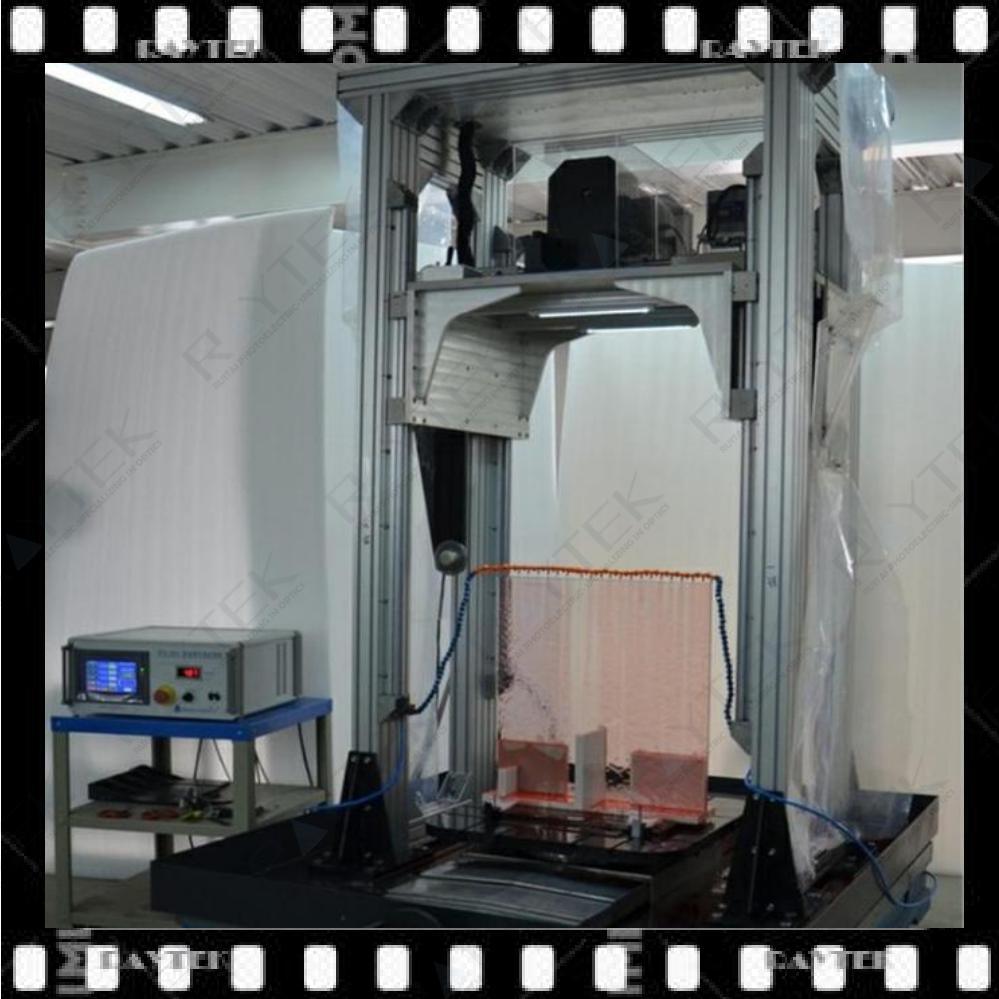

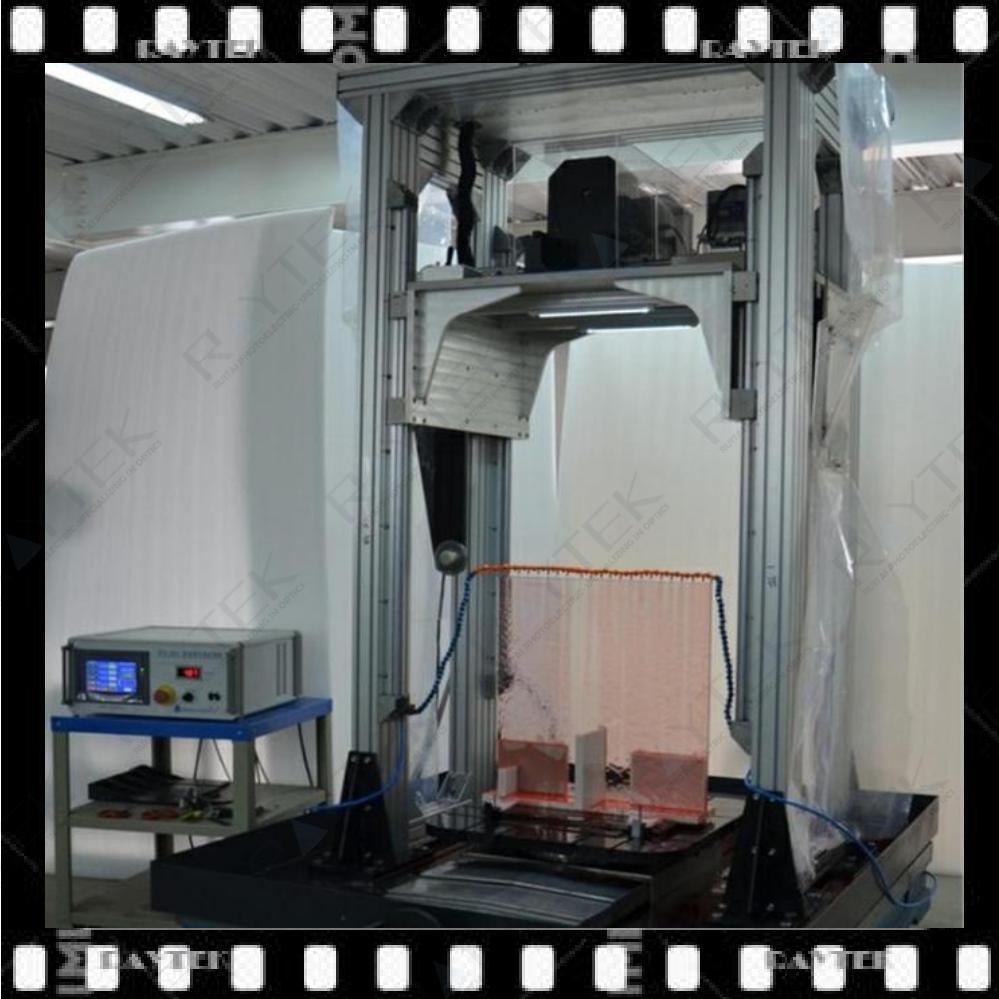

Custom Manufacturing Capacity 2: Ultra big size Quartz/Silicon/Sapphire Ingot CNC Multi-Wire Saw Cutting

Multi wire cutting machine can be used to cut sapphire, magnetic materials, crystal, optical glass, piezoelectric ceramics, tungsten, molybdenum and semiconductor (single, polycrystalline silicon) and other brittle and hard materials. Multi wire cutting technology is an advanced slicing technology in the world. With the rapid development of China's information industry, especially the semiconductor industry, the demand for sapphire chips is increasing, and the accuracy requirements are also increasing. However, the traditional internal cutting method of silicon wafer and sapphire in our country has low precision, easy loss and high cost. The traditional sapphire cutting method uses internal slicer to cut with diamond grinding wheel or magnetic tile, and mainly uses WEDM, which can not meet the requirements of thin cutting sapphire, which has become the bottleneck of industry development. Raytek's ultra large size quartz ingot and sapphire multi wire cutting machine has been widely used in Raytek optical material production line because of its high precision, high efficiency and low loss. Raytek quartz ingot/monocrystalline silicon / polycrystalline silicon/sapphire multi wire cutting machine adopts diamond wire, the cutting efficiency is 1.5 times of the traditional oil sand wire cutting semiconductor, greatly reducing the single chip cutting cost and wire breakage rate, improving the cutting quality.

Main Processing Technical Capacity Data:

Main Cutting Technologies Characters:

1).Cutting bending (bow) is small

2).The warpage of cutting is small

3).Cutting parallelism (TARP) is good

4).The total thickness tolerance (TTV) of cutting is small

5).The cutting loss between cutting chips is less

6).Shallow damage layer on wafer surface during cutting

8).The cutting roughness is small,

9).High rate of slicing by cutting

10).High cutting efficiency

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products & OEM & ODM service with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.