Description

Solar cells are divided into crystalline silicon and amorphous silicon. Crystalline silicon cells can be divided into single crystal cells and polycrystalline cells; The efficiency of monocrystalline silicon is also different from that of polycrystalline silicon. The following is a brief introduction to the material of solar silicon wafer and the purpose of solar silicon wafer.

What is the material of solar silicon wafer

Solar cells are divided into monocrystalline silicon solar cells, polycrystalline silicon thin film solar cells and amorphous silicon thin film solar cells.

A form of elemental silicon. When the molten silicon is solidified, the silicon atoms are arranged in diamond lattice into many crystal nuclei. If these crystal nuclei grow into grains with the same crystal plane orientation, these grains will be combined in parallel to crystallize into monocrystalline silicon.

Polysilicon is a form of monocrystalline silicon. When molten single silicon solidifies under supercooling conditions, silicon atoms are arranged into many crystal nuclei in the form of diamond lattice. If these crystal nuclei grow into grains with different crystal plane orientation, these grains combine to crystallize into polycrystalline silicon.

Amorphous silicon is prepared from amorphous alloys. In order to obtain amorphous silicon, a high cooling rate is required, and the specific requirements for the cooling rate depend on the material. Silicon requires a very high cooling rate. At present, amorphous state can not be obtained by liquid rapid quenching. In recent years, many techniques for vapor deposition of amorphous silicon films have been developed, including vacuum evaporation, glow discharge, sputtering and chemical vapor deposition. Generally, the main raw materials used are monosilane (SiH4), disilane (si2h6), silicon tetrafluoride (SiF4), etc., with high purity requirements. The structure and properties of amorphous silicon film are closely related to the preparation process. At present, it is considered that the quality of amorphous silicon film prepared by glow discharge method is the best, and the equipment is not complex.

Application of solar silicon wafer

Convert light energy into electricity. Simply put, because the energy of photons irradiates the electron hole position in the semiconductor pn junction composed of silicon and germanium, the electrons will jump, resulting in a voltage in the semiconductor silicon at both ends. If the voltage forms a circuit, a current will be generated.

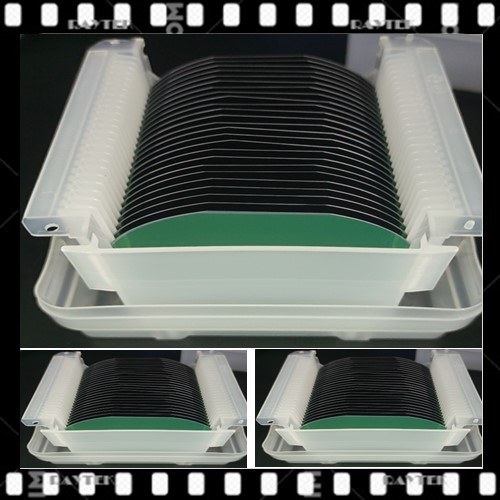

Main Size Specification:

G1,M2,M6,M10,G12

Main Technical Data:

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.