Description

Due to the great innovation and improvement of traditional VAD (vapor phase axial deposition) method in optical fiber fabrication technology, Raytek / c-laser has successfully developed the latest synthetic fused silica material cfs-100. The purity of Raytek/C-laser CFS-100 is very high, and its OH content is lower than that of traditional process, Raytek/C-laser CFS-100 is a kind of high-quality synthetic fused silica which can be widely used in semiconductor and liquid crystal display industry. In terms of optical properties, Raytek/C-laser CFS-100 adopts advanced manufacturing technology and process. Therefore, in addition to heat resistance, mechanical strength and chemical resistance, it also has high ultraviolet transmittance, high purity and excellent weather resistance.

.

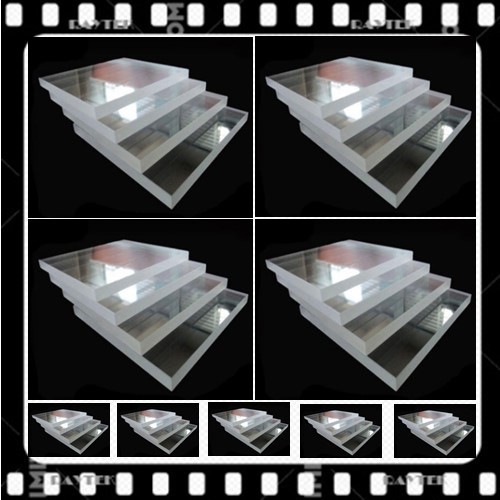

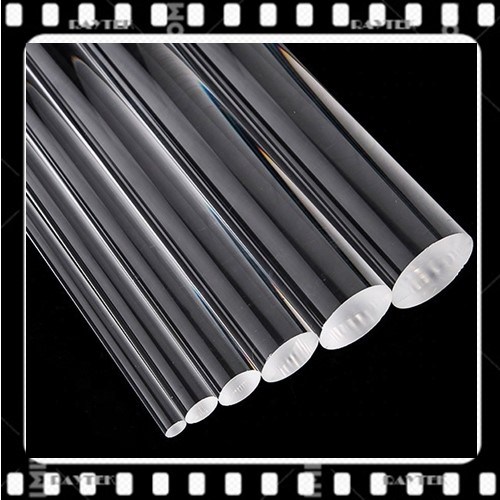

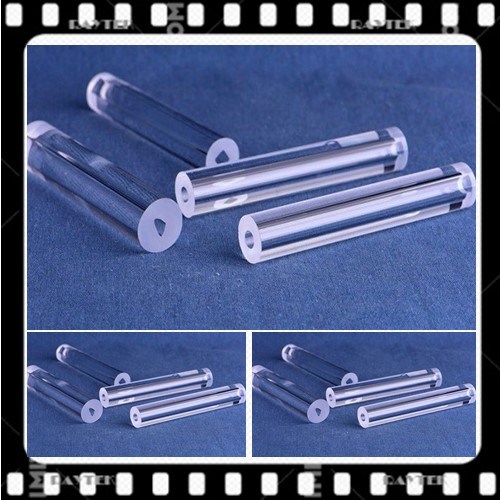

Products Name: VAD Fused silica

Alias: VAD Fused silica, VAD-process Synthetic Fused Silica, Synthetic Fused Silica ,Fused silica glass, Fused silica, C-laser fused silica, quartz glass, quartz, Corning fused silica, Ohara fused silica, Schott fused silica, optical fused silica, optical quartz, optical fused silica glass, optical quartz glass, fused quartz, etc

Main Characteristics:

Raytek/C-laser Synthetic fused-silica offer a number of advantages over glass or fused quartz:

1).Greater ultraviolet and infrared transmission

2).Low coefficient of thermal expansion, which provides stability and resistance to thermal shock over large temperature excursions

3).Wider thermal operating range

4).Increased hardness and resistance to scratching

5).Much higher resistance to radiation darkening from ultraviolet, X-rays, gamma rays, and neutrons.

6).Optical-quality synthetic fused silica (OQSFS)

7).Low Hydroxyl content

8).High transmittance

9).Low cost.

Impurity content analysis

Chemical resistance:

Mechanical Properties:

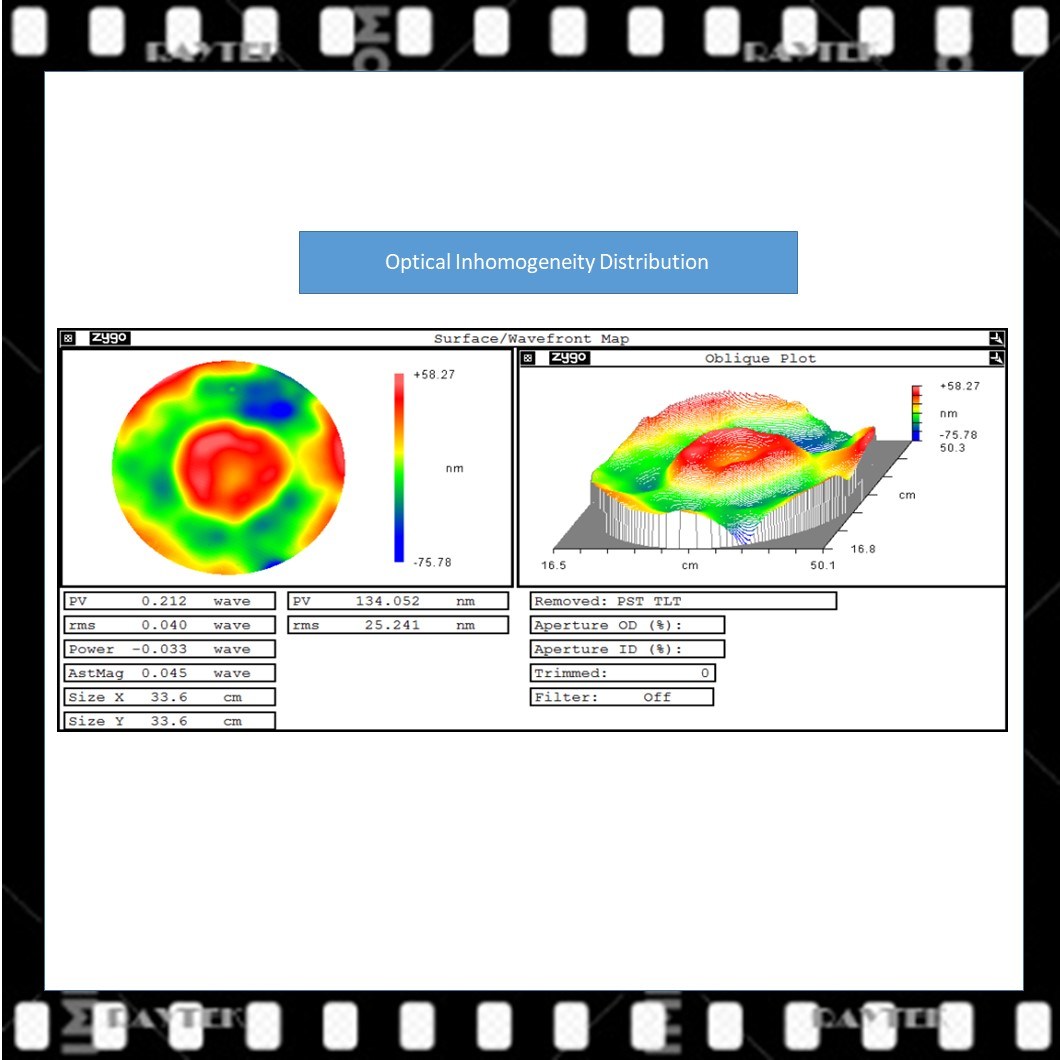

Optical Properties:

Main Applying Fields:

Matching Custom Manufacturing Serivce:

Including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

Matching processing equipments;

1).Single side lapping and polishing machines

2).Duble sided polishing machines

3).Ring throwing machines

4).DMG five-axis five-linkage spherical milling machine

5).DMG ultrasonic machining center

6).Super large scale gantry cnc machining center (2.0*2.0m)

7).Super large scale surface grinder (1.6m*1.6m)

8).CNC cutting machines

9).Thin plate cleaning machines

10).Ultrasonic trough cleaning machines

11).Plane interferometers

12).Two dimensional detectors

13).Ion beam polishing machines

14).Magnetorheological polishing equipments

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.